How HBI Group ASIA Ensures Agro Commodity Quality Control

In the dynamic market of Asian agro-commodity exports, quality control is not a luxury—it is the non-negotiable foundation of successful trade. As highlighted by common misconceptions about Asian agro commodity exports, the risk of fraud, contamination, and grade misrepresentation is high.

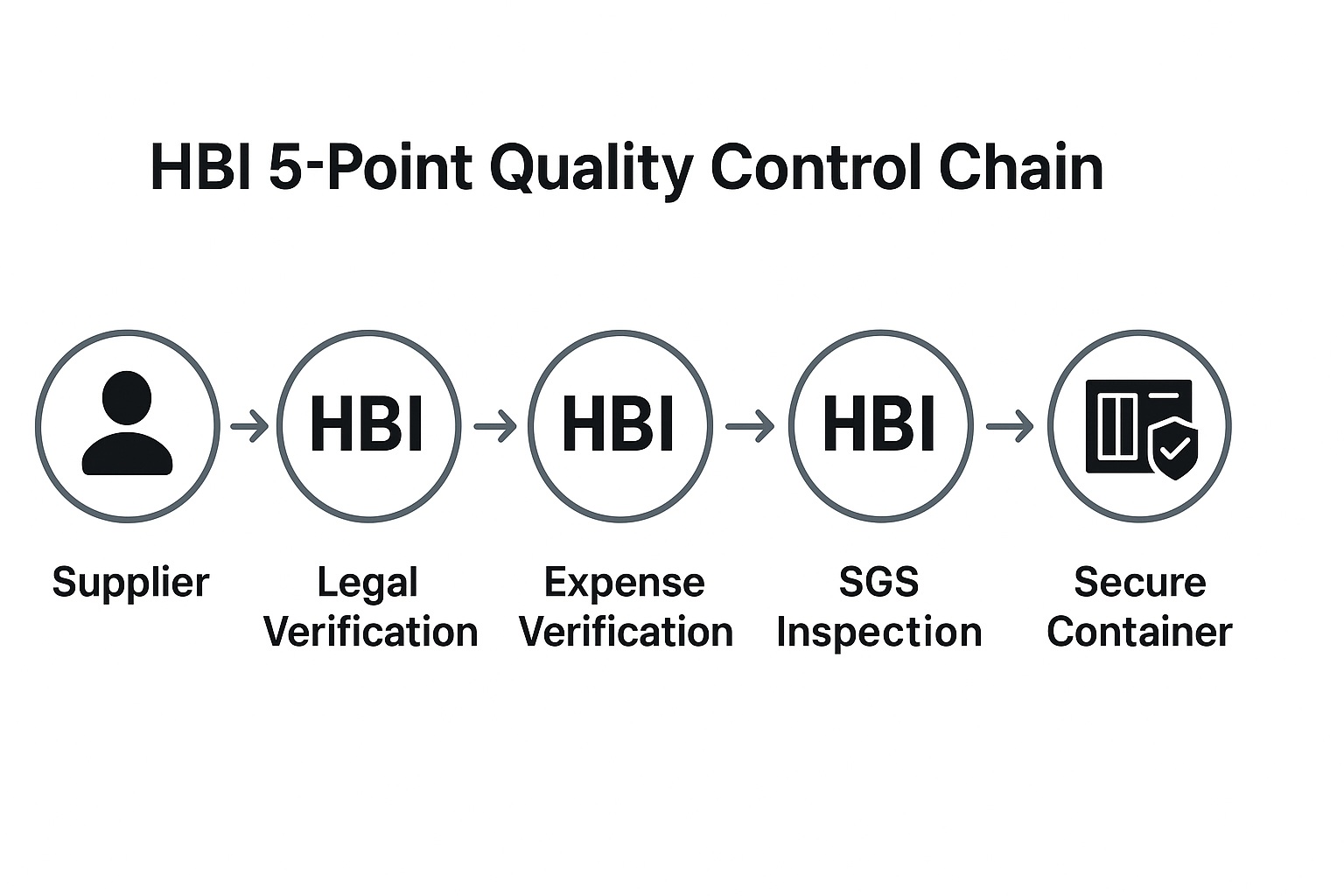

At High Business International, our mandate is simple: eliminate risk by controlling every operational touchpoint. This proprietary, end-to-end HBI Group Asia Commodity Quality Control system is what differentiates us, ensuring every metric—from moisture to container seal—is guaranteed.

Here is the proven, 5-point process HBI Group Asia employs, following the commodity’s journey from the mill floor to the sealed container.

Layer 1: Pre-Export Processing Standards

Precision Moisture Control

Moisture is the single greatest threat to cargo quality during long transit. Our supervisors rigorously test and verify moisture levels, ensuring they fall within narrow, contractually acceptable ranges (e.g., typically 13.5% maximum for rice), which aligns with international commodity grading standards. This precise control is the first defense against mold, spoilage, and significant weight loss.

Meticulous Grading, Sorting, and Milling

We provide dedicated oversight of the milling process itself. This confirms that the final output matches the buyer’s contracted grade—whether it is 5% broken rice, specific kernel length, or bean screen size. We monitor certified milling procedures to reject any batch that does not meet the technical specification before it moves to storage.

Layer 2: Secure Packaging and Warehouse Management

Optimized Packaging for Transit

The correct packaging material is vital. We verify the use of appropriate new food-grade bags or container liners to prevent contamination and external moisture ingress. This step includes strict verification of product weight and clear, tamper-proof labeling before the product is stored.

Inventory Control and Warehouse Integrity

HBI verifies that the inventory is secured in controlled, non-commingled warehouses. This prevents product from different suppliers or grades from being mixed before shipment, maintaining the integrity of the order established during our initial sourcing process. This is a critical step in our comprehensive Import Raw Materials Asia service.

Layer 3: The Critical Shipping Gateway

Continuous Loading Supervision and Container Sealing

This step directly solves the common “SGS Fraud Gap.” HBI supervisors are present throughout the entire container stuffing process. They monitor the container until the final piece is loaded, ensuring there is zero substitution with inferior cargo. The container is then secured using HBI proprietary seals with documented sign-off before the container leaves the yard—a standard feature of our Cooperate Gold Program.

Final Documentation and Quality Sign-Off

The final quality control checkpoint is the paperwork. We match the physical cargo quality report against all required final documents—Bill of Lading (BL), Phytosanitary Certificates, and Certificate of Origin—before issuing the final quality sign-off required for payment release. This final paper audit ensures that the legal and physical consignment are perfectly aligned, completing our verification and fraud prevention chain.

By maintaining a presence at every stage, HBI Group Asia removes the uncertainty from your supply chain. Our HBI Group Asia Commodity Quality Control process transforms Asian sourcing from a high-risk operation into a reliable, verifiable supply stream.